Table of Contents

Why are latex mattresses so expensive?

The white gooey sap from the rubber tree is the main ingredient in latex foam that makes up the core of natural latex mattresses. Consequently natural latex mattresses are among some of the most expensive mattresses that you can buy. It is hypoallergenic and biodegradable. It is longer lasting, more supportive, more contouring then memory foam. However it is more expensive, on average about twice the price the same size mattress with a memory foam core. A king size mattress with a natural latex foam core and organic cotton cover with wool batting starts at about $2600 while a memory foam mattress of the same size will cost half as much.

So how does tree sap become a bed and why are natural latex mattresses so expensive?

Understanding Why Are Latex Mattresses So Expensive?

Latex sap harvester in Guatemala start their day in the early morning before many people wake. The high humidity at this time of day makes it so that the tree will produce more latex when the bark is cut then that other times of the day. If it gets too hot and dry, then the trees do not produce optimally and the latex coagulates much faster. This means that it slowly turns to a solid much like how when you get a cut on your skin the blood flows out at first but then starts coagulating in order to seal the wound and stop the flow of blood out of the body.

Some of the rubber tree plantations like the one featured in this video in Guatemala have over 1 million rubber trees that need to be tended to and harvested. This is a monumental task that requires careful attention and skilled labor. A worker on a plantation might carve 700 trees a day to extract the latex sap. The workers carve a ridge in the bark of the latex rubber tree in a downward diagonal or corkscrew pattern close to the base of the tree and install a ledge at the bottom of this diagonal carved ridge that will make the latex flow into a receptacle. After sometime the latex in the receptacle is emptied into a larger bucket or plastic can. The workers then haul these buckets and plastic cans out of the plantation and onto a cistern truck. This truck then head to the processing facility where the latex is conditioned before being baked into the latex foam that is featured in some of the worlds finest mattresses.

Meeet a latex plantation worker

One of the workers in the video named Doroteo Blanco and describes the latex of having a nice sweet smell when it flows out of the tree. The tools that are used in harvesting are a special knife that has a blade that makes a 90° angle. The workers carry some disinfectant a belt mounted bottle. The special carving knife is dipped into the disinfectant to prevent disease transfer from one tree to another. The workers also use a flexible straight edge to mark the carving line in a spiral pattern at the base of the rubber tree.. This straight edge also acts as a measuring device to measure the areas on the tree bark that will be arrested in that year. This way the tree will not be over harvested for its latex and has less chance of developing disease.

If the carving is not done right, then the tree can develop knots or shrink and the tree will not be able to be harvested for its sap in subsequent years. Doroteo, is an extremely precise carver and has been honing his craft on latex trees for the past 20 years.

After carving the tree, the harvesters wait about four hours before collecting about a litre to a litre and a half of sap per tree. If the harvesters wait too long to pick up the latex from the receptacle, but may congeal and be useless for making latex foam. It may be used for other products like car tires.

Doroteo manages to collect about 140 L a day in the summer low season, and double that about 280 L in the winter season. He cuts about 600 to 700 trees per day and works on three trees about every minute. Very experienced latex harvesters cut up to four trees per minute.

The workers consolidate all of this app into tanks at the processing facility. Then, they let it sit for about 12 hours. It is then processed in a centrifuge. This process separates the water from the rubber. Then, the latex sits for another 45 days in order to let it stabilize.

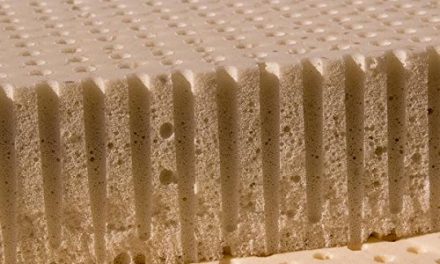

After the late text has set for 45 days, it is then turned into latex foam using the Dunlop process. The Dunlop process is nothing new. It has been around since the 18th century and is a process for turning liquid latex into durable, supportive, contouring, nontoxic foam. During the initial process the liquid latex is mixed with a concoction of stabilizers so that it achieves a uniform air cell structure as it bakes. The latex is frothed up in a VAT to achieve the correct density. A gelling agent is then added. Then the latex is poured into a mould and radio waves are projected through it in order to harden, or vulcanize the latex.

In the factory that is featured in the video, about 40 tons of liquid latex moves through the factory. About 50 kg of liquid latex is needed to make a 30 kg latex foam. Once the latex foam core is baked it is washed rinsed dried and then compressed in order to prepare it for shipping. It is then shipped off to various mattress. manufacturers for assembly.

The latex plantation that is featured in the video has been run by the same family for about 50 years. The duration that a latex tree can be tapped is about 40 years. Then it has reached the end of its sap producing life.

Why you should look for the GOLS and FSC certifications when buying a mattress

The Guatelinda plantation that is featured in the video has about 2000 acres of rubber trees. The Guatelinda plantation is certified by FSC (Forest Stewardship Council). This certification ensures that the plantation uses no child labor, is organic, and abide by the local employment laws. The same plantation is also certified by GOLS (global organic latex standard) which certified that the latex phone is made up of over 95% certified organic latex. The GOLS certification ads reassurance to the buyer of a natural latex mattress that carries this certification, but it also adds a dollar value to the final sale price.

In the beginnings of the car in the street in the early 1900s the demand for rubber exploded and many plantations were started at this time. There were so many that this led to a drop in prices and consequently a drop in wages and working conditions for the harvesters of the latex foam on the plantations in Central America, South America, and south east Asia.

Latex prices on the global market fluctuate from year to year. For example in 2010, the price was very high. This pushed plantations and developers that were starting plantations to acquire a lot land and at the same time a lot of debt to maximize the earnings from the high prices. But soon after, the demand fell and so did the prices. Low prices put plantation workers at a higher risk of exploitation. This is why certifications like FSC and GOLS are so important. They are there to ensure that the workers are fairly treated and are not exploited.

The Global Demand For Organic Latex Mattress models is increasing

In 2021 the global latex mattress market was evaluated at $9.7 billion. This number has the potential to double by 2030.

It is also difficult to maintain prices with certain unforeseen events like hurricanes which bring a lot of rain and consequently damage some parts of the plantations. In this instance the latex trees have access to too much water and the latex is of a poor consistency. Furthermore, hurricanes and heavy rainfall can wash out roads which can render parts of the plantation in accessible.

A drought can also produce unfavourable conditions for latex explanations. In this instance the trees do not produce enough latex to make it worthwhile to harvest. them.

Workers on unregulated plantations that are not certified by FSC or GOLS maybe exposed to harsh working conditions, 12 hour days or above and toxic chemicals. That’s why plantations are certified by GLS and FSC produce a win-win for the customer as well as the workers. The workers benefit from higher wages and better working conditions, and the consumer profits from a organic material that is nontoxic and durable.